ENVIRONMENTAL PROTECTION

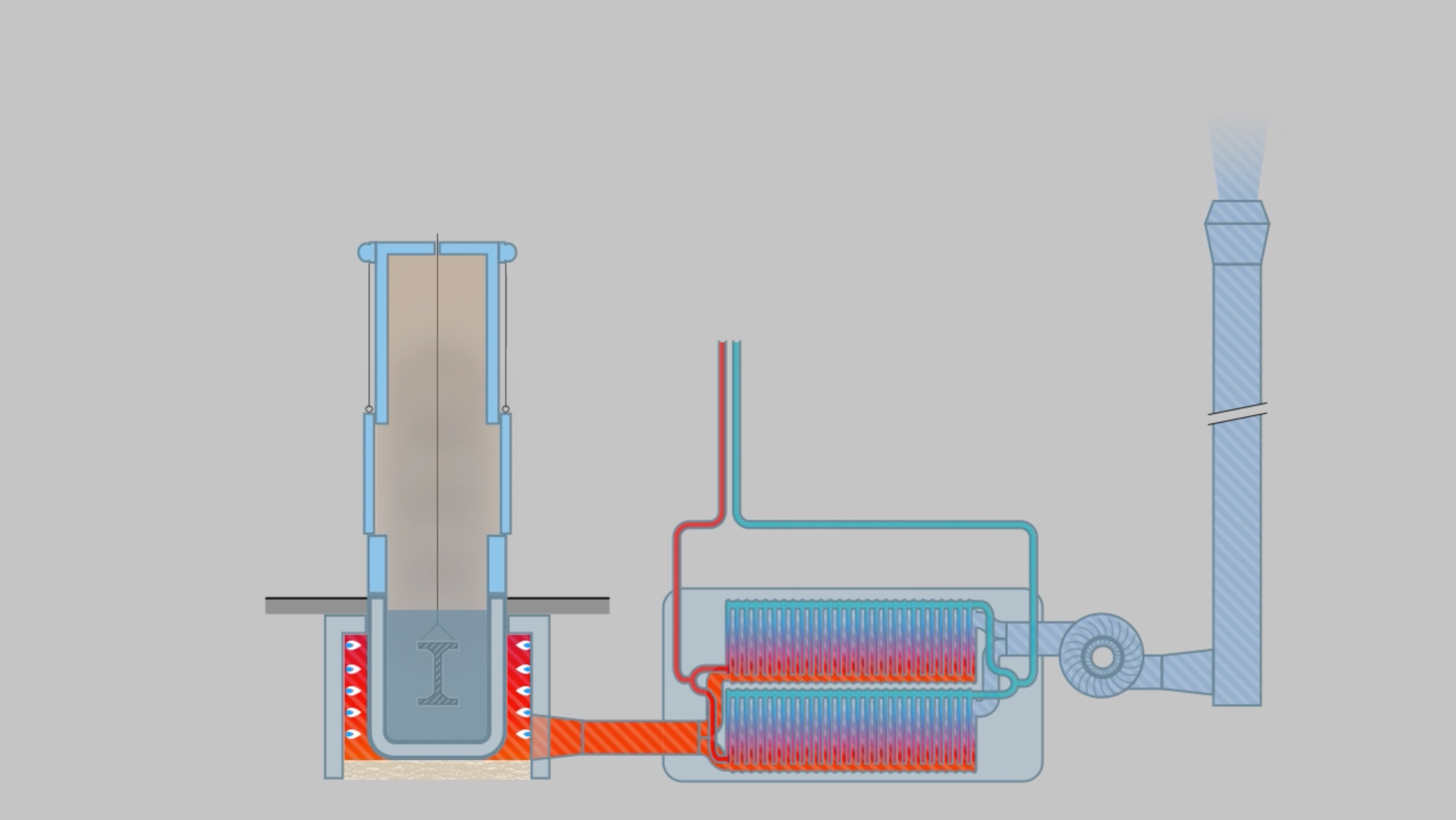

Waste heat recovery from the zinc kettle

The animation shows the schematic structure of waste heat recovery from the flue gas from the galvanizing kettle.

The temperature of the exhaust from the combustion chamber is approx. 550 °C. Using an air-water heat exchanger it is possible to make use of the heat energy for other purposes, e.g. to heat the pre-treatment bath or offices and staff rooms. The temperature of the exhaust in the chimney is now only approx. 80 °C.