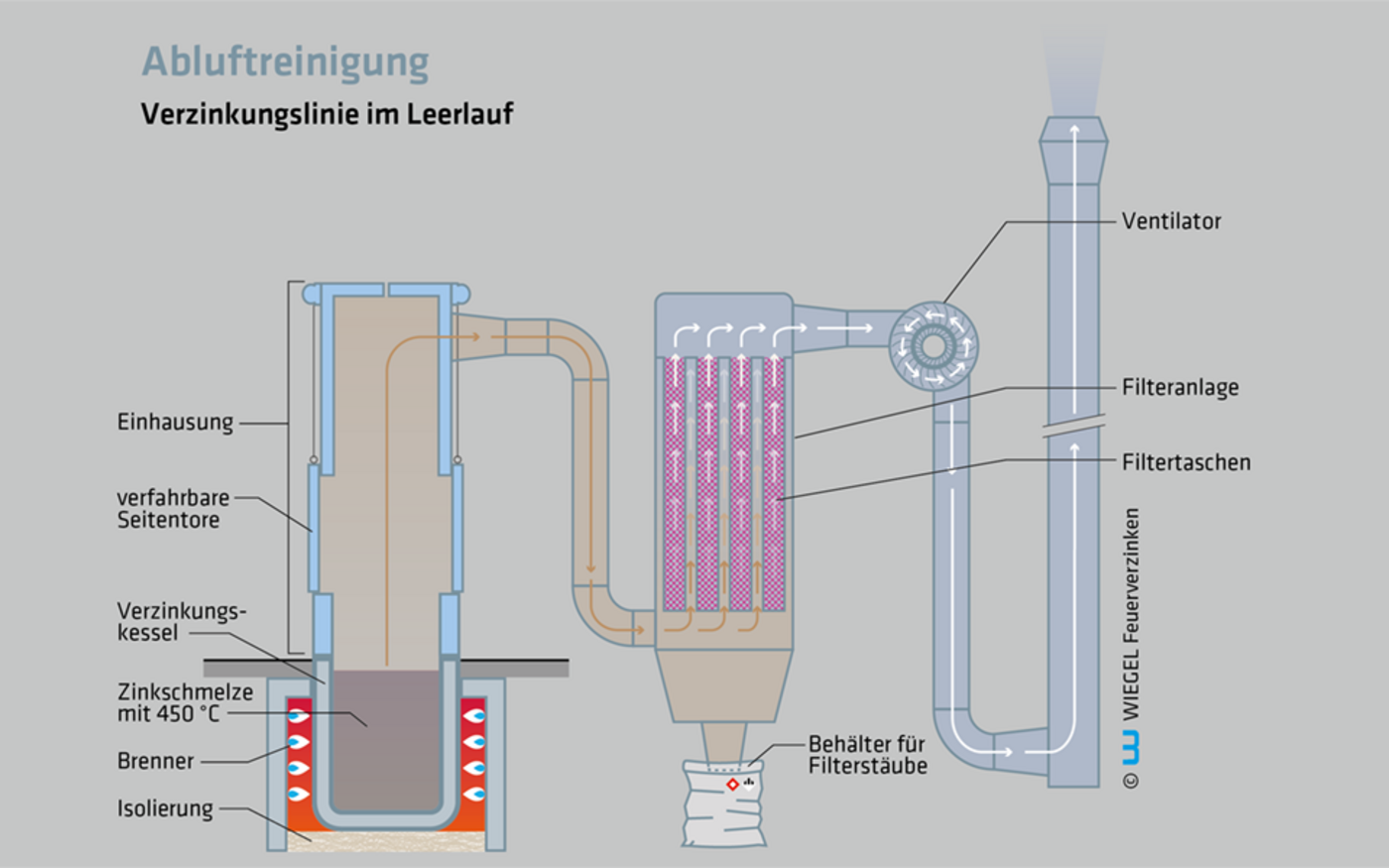

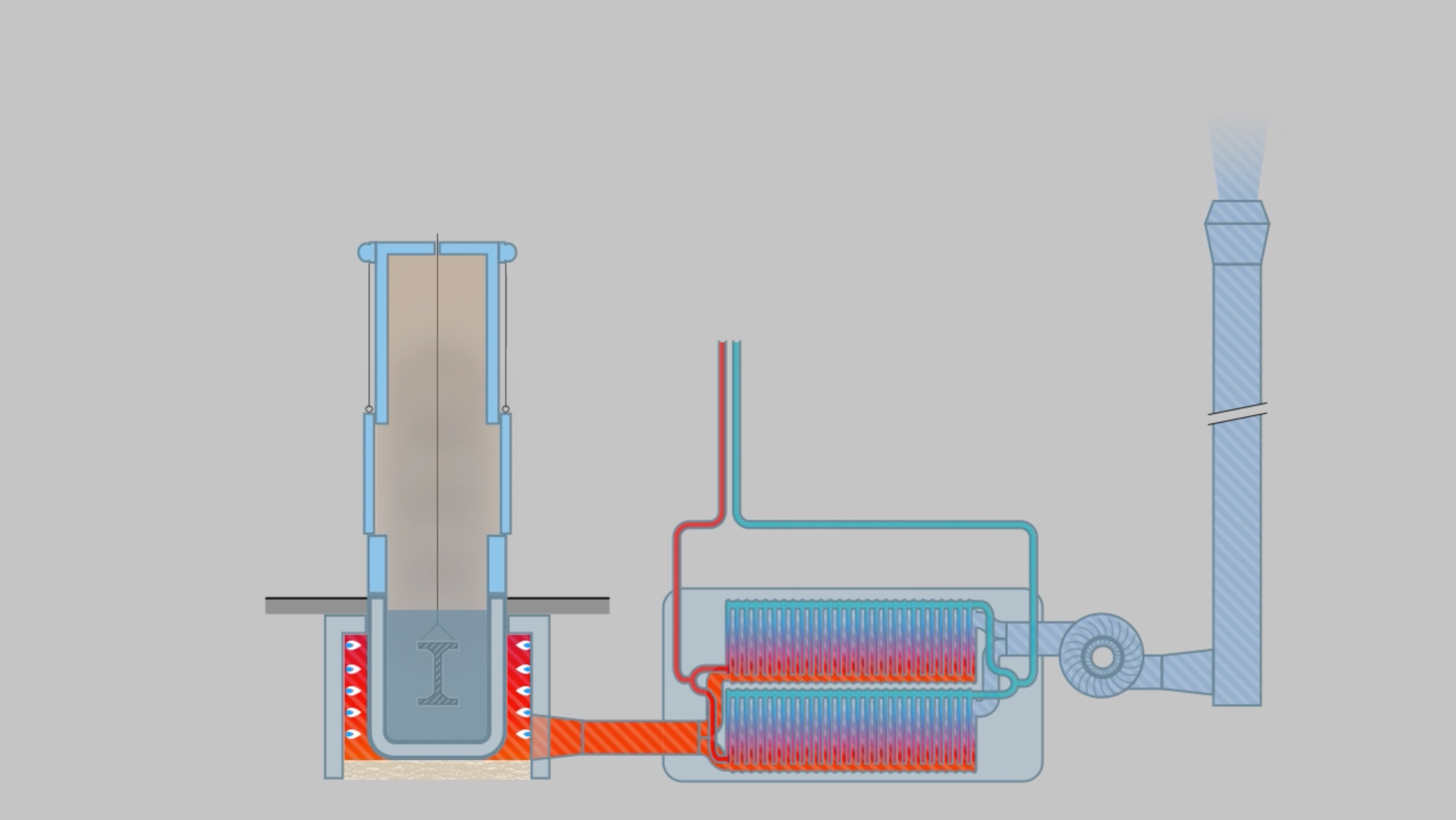

The animation shows the schematic structure of the pre-treatment line and the associated air purification system.

The pre-treatment line is completely enclosed in order to prevent release of hydrochloric acid vapour and ammonia to the surrounding air. The negative pressure ensures that no contaminated air can escape, even when workpieces are entering the pre-treatment hall. The extracted air is cleaned using an air scrubber.

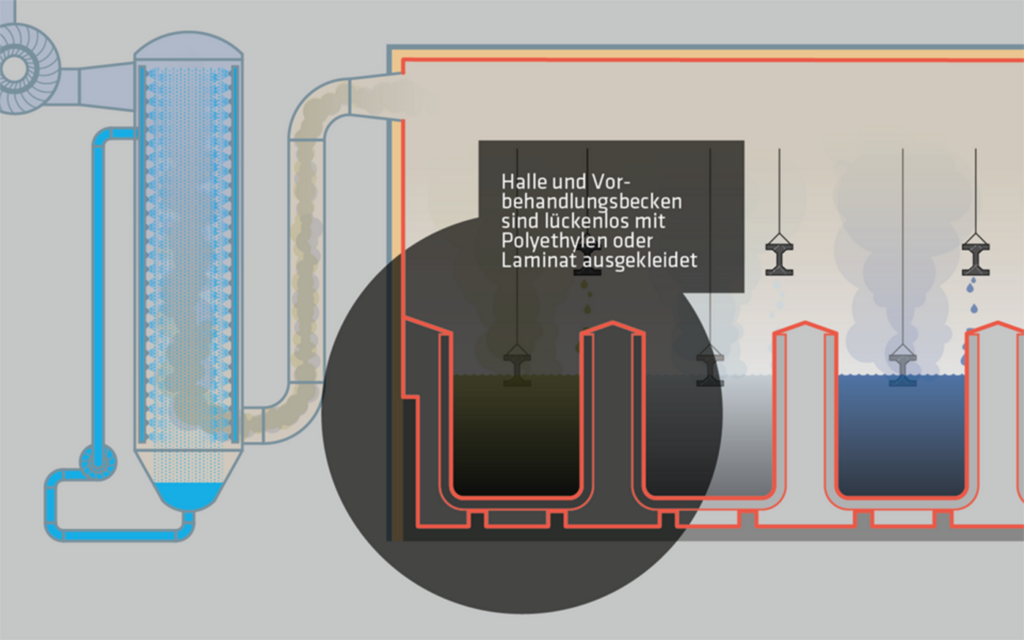

Enclosed pre-treatment line (VBL) with air purification, details:

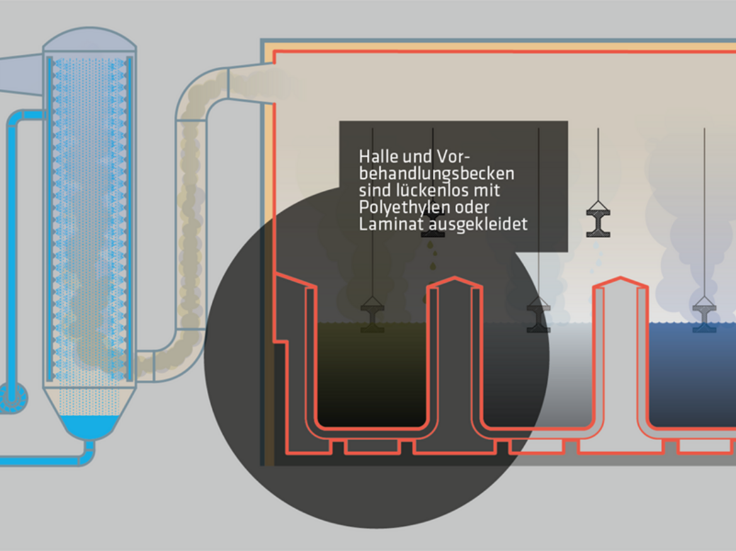

1. Seamless seal

The basins of the pre-treatment baths as well as the collecting basins are completely and seamlessly sealed with polyethylene or laminate. The capacity of the collecting basins is 100% of the total volume, ensuring full spill protection.

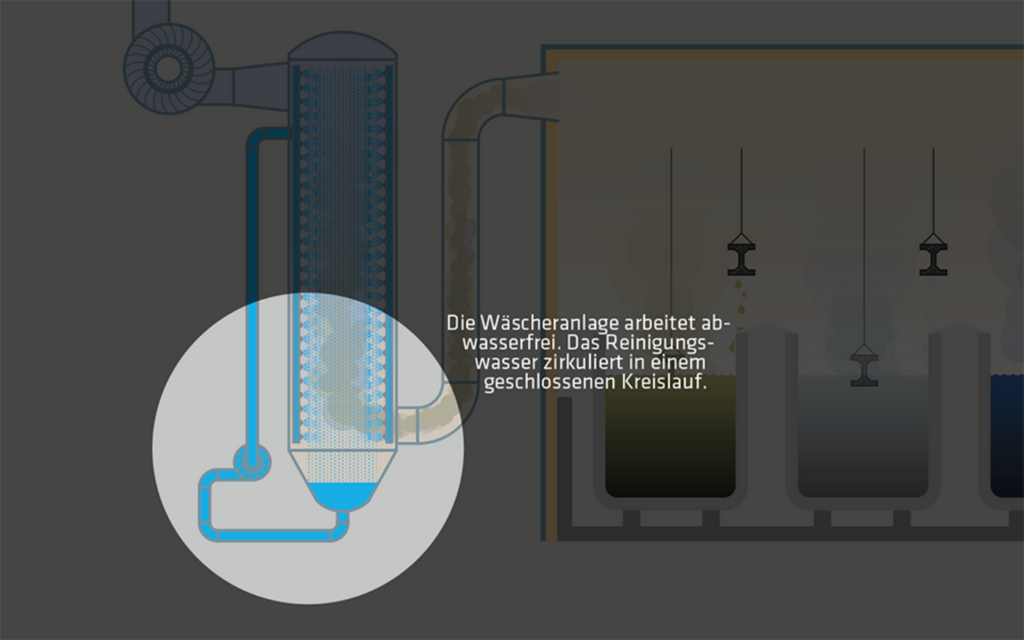

2. Waste-water-free operation

The scrubber is operated in circulation mode. Like the entire pre-treatment line, it has no connection to the waste water system. Once the scrubber water is sufficiently loaded with residues it can be reused in the pickling baths by increasing the hydrochloric acid concentration, or it is recycled by a certified recycling company.

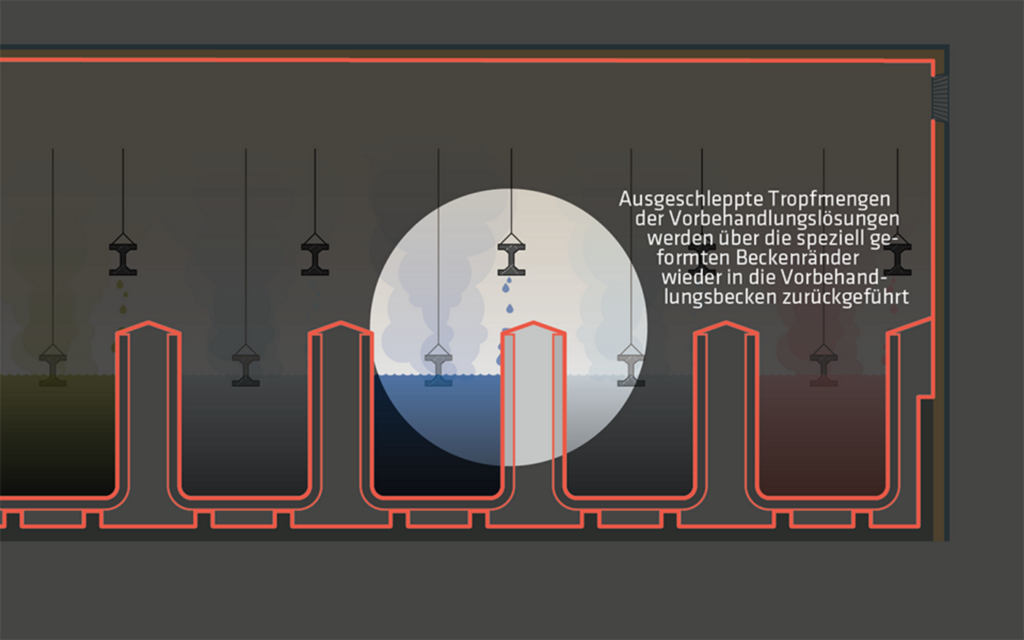

3. Drip return

Thanks to the special design of the lining between the baths, any spillage that drips from the workpieces flows back into the baths. There is no “ground sump”.